VEGA 3.90 M

Productivity and quality

The Vega Medical is the dedicated solution for knitting of orthopedic or medical items developed by the specialists in our Stitch Lab.

Before the presentation of the Vega M, medical knitting machines were adapted from fashion models. With the Vega M, the decision was made to design a product exclusively dedicated to this specific application using in-lay elastic yarns. This

choice has allowed the design team to select all the optimal technical solutions without concession to other applications. The result is a significant increase in machine performance with an

improvement in every factor that compose the Overall Equipment Efficiency = availability x productivity x compliance.

The machine is available with 130 cm or 90 cm E14 needle-bed with 2 or 3 knitting systems.

DTC: Ensuring enhanced Product Quality

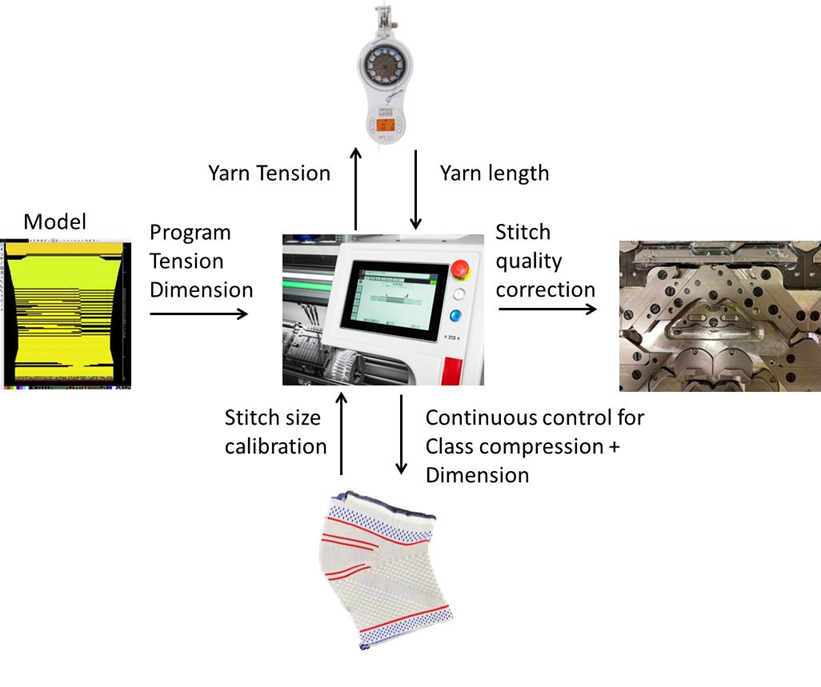

The Vega M includes a system called Dimension and Tension Control (DTC) to ensure the geometry and the compression class of the final article. It is based on 4 systems:

– Remote control of the yarn tension

– Measure of absorbed yarn length (LFA)

– Stitch quality correction

– Take down drive using a close loop control.

The compression class, which is ensured through the use of the elastane yarn and the dimension of the final product, are programmed directly by Model 9. In order to secure dimensions adapted to the patient limb, the DTC system calculates the yarn length required to knit each zone

of the article. The variation of the stitch quality sets the vertical stitch dimension and guarantees the exact size of the custom made orthotics.

The Dimension and tension control (DTC) therefore guarantees that the final article corresponds to the specification required by the therapist.

technical specifications

Carriage cambox

Short, light, the cam-box has been designed exclusively for medical application.

Single head without cam carriage bridge,

with direct yarn feeding from the top.

Three systems cam boxes each with integrated bi-directional transfer.

Unlimited patterning possibility with the

Three-Way-Technique.

Integrated split-stitch function.

Stitch length controlled electronically with

possibilities to modify any time.

Electronic needle selection

Needle bed

Working width 90 cm (130 cm in option)

The new clamp and scissor system ensures that the yarns of the yarn-carriers are independently gripped. Gears prevent the yarn from escaping and guaranty the correct yarn gripping or cutting. High intensity LED ribbons illuminate the needlebed and highlight the formation of the stitch.

Automatic greasing system

Auto cleaning by venture

Yarn carriers

Equipped with 16 motorised yarn carriers

Outside creel with 16 yarn tensioners (option)

independently programmable yarn carriers

Unique device for in-lay for technical articles

Automatic control of the yarn supplier by Model program (option)

The automatic calibration of the yarn-guides using sensors installed on the cam-box allows continuous monitoring of the yarn-guide position accuracy.

Kit for supporting yarn feeding unit (option)

Dimension and Tension Control

The Vega M includes a system called Dimension and tension control (DTC) to ensure the geometry and the compression class of the final article. It is based on 4 systems: Remote control of the yarn tension – Measure of absorbed yarn length (LFA) – Stitch quality correction – Take-down drive using a close loop control.

The compression class, which is ensured through the use of the elastane yarn and the dimension of the final product, are programmed directly by Model 9. In order to secure dimensions adapted to the patient limb, the DTC system calculates the yarn length required to knit each zone of the article. The variation of the stitch quality sets the vertical stitch dimension and guarantees the exact size of the custom made orthotics. The Dimension and tension control (DTC) therefore guarantees that the final article corresponds to the specification required by the therapist.

DriveS

Carriage brushless motor adjustable from 0

to 1,60 m / sec. max.

Yarn carrier encoders

Upper take down system with possibility of

reversing drive

Sinker system

The main innovation arises from a completely new sinker system. The perfect guiding of the sinker using a sinker bed and a new activation system has resulted in an optimal maintaining of the elastic yarn during the creation of the stitch. No elastane is knitted together with the base yarn even with an increased production speed. This function is programmable. During a knitting row it can be activated or deactivated several times according to the defined program

Controls / Security

S-Touch 2.0

All necessary devices to stop the machine in case of yarn breakage, knot, running out of

yarn, shock, fabric

Press-off, over-heating motors, load-up detector

Reserve battery (in case of power failure)

Load – up detector

Self diagnostic

Preventive Maintenance which helps to limit the unplanned machine stops. The machine indicates when the necessary maintenance actions must be done and by whom. Information is available not only on the machine itself but also on

Backup capacity 1 Giga

Network 10/100 Mbps

10” color touch-screen interface

Interface _USB stick

Netcontrol production control

Dimensions

Length: 2510 mm

Height: 1420/2200 mm

Width: 790/1320 mm

Weight: 850 kg

Power consumption: AC400V +-10% ; 50Hz ; 1.5 KW